ZWAG Pressure Filter: Theory of Operation

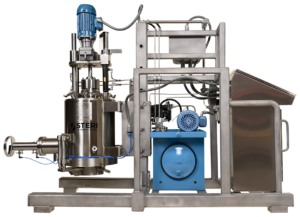

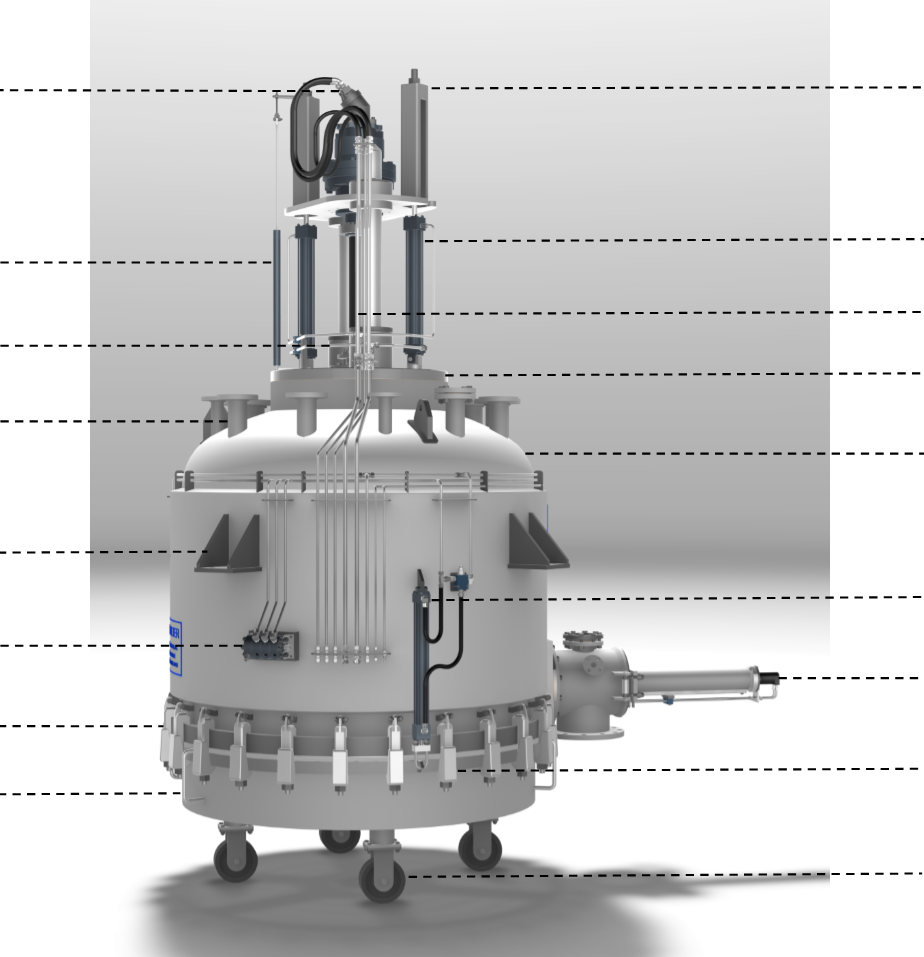

The ZWAG Nutsche pressure filter is a single plate filter which is located at the bottom of the vessel. The single-plate filter allows build-up of a large amount of cake. This is beneficial for slurries that contain up to 70% solids.

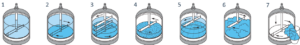

During filtration, externally applied pressure forces the slurry downwards through the filter plate and the filtrate exits through a nozzle centered under the filter plate. Most filters rely, to varying extents, on the solids left behind on the filter surface to achieve maximum effectiveness, essentially using the solids, commonly called cake, to trap more solids. The thick cake that builds-up in a Nutsche filter can crack. Slurry will take the path of least resistance and flow through the cracks and not the cake, thus compromising filtration.

The ZWAG Nutsche filter uses a motor driven, rotating agitator inside the vessel to continuously smooth the cake and keep it evenly distributed. Simultaneously, hydraulically driven actuators move the agitator vertically to follow the growth of the cake.

Once the filtration process is complete, the cake can be washed and re-slurried by the agitator to achieve greater cake purity. The ZWAG pressure filter offers the flexibility of vacuum and/or hot gas drying to achieve the correct cake consistency. After the cake has been dried the side discharge valve is opened. The agitator rotation is reversed to push the cake out through the open valve.

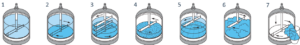

- ALL-IN-ONE OPERATION: Sized for your production batch, your ZWAG is never a bottleneck.

- STIRRING FOR SLOWFILTERING PRODUCTS: After filling, continuous stirring just above the filter plate reduces filtration time.

- UNIFORMITY FOR QUICKFILTERING PRODUCTS: The cake is layered with evenly distributed particles by progressively raising the agitator blades.

- PRESS FOR QUALITY: The agitator smooths down the cake to close cracks and create a uniformly permeable structure.

- WASH FOR QUALITY: Liquid is sprayed evenly over the cake for thorough diffusion washing, and can be easily re-slurried for greater purity.

- UNIFORM DRYING: Solids are kept moving over the heated bottom for speedy, complete drying.

- TOP DOWN DISCHARGE: The agitator blades scrape the cake through the side door from top to

Efficiency

Simple concepts, well-orchestrated, enhance performance:

- Active agitation promotes homogeneous cake and speeds filtration

- Washing and reslurrying eliminates impurities

- The single plate filter speeds cleaning and/or change-over for successive batches of different products and eliminates cross contamination

- Built-in vacuum drying reduces product handling

Its compact design makes one person operation easy and safe. Engineered and built to the most exacting standards, the ZWAG filter is a reliable, low maintenance workhorse.