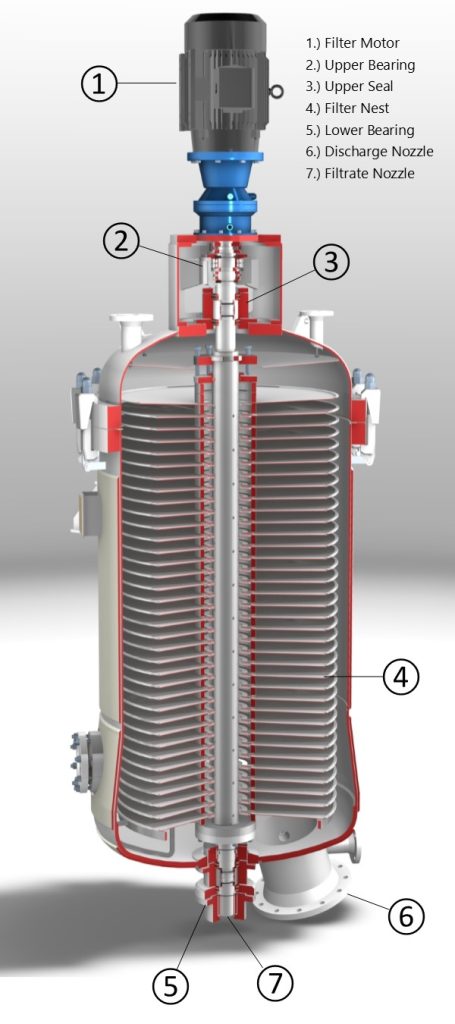

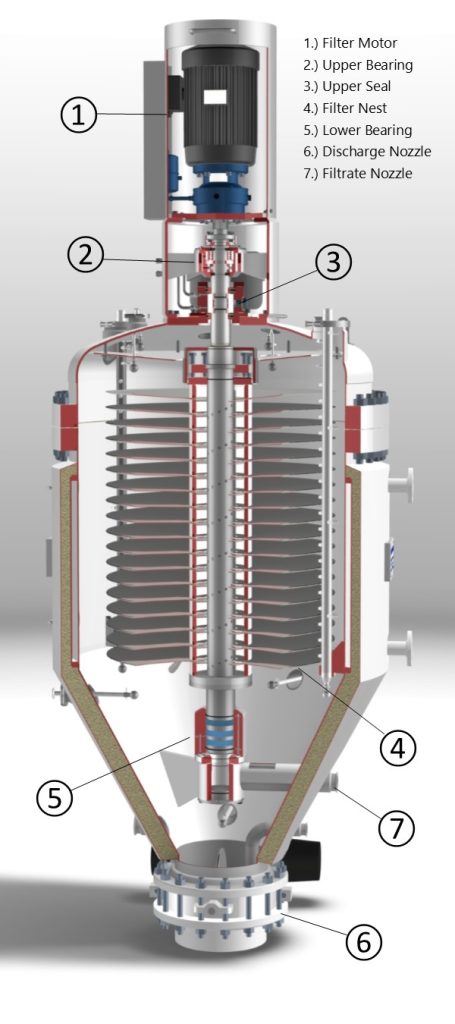

Theory of Operation: FUNDA Cake Filtration

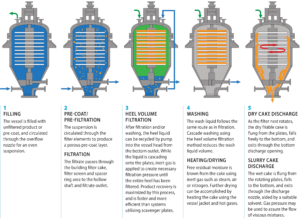

Filling

Filling

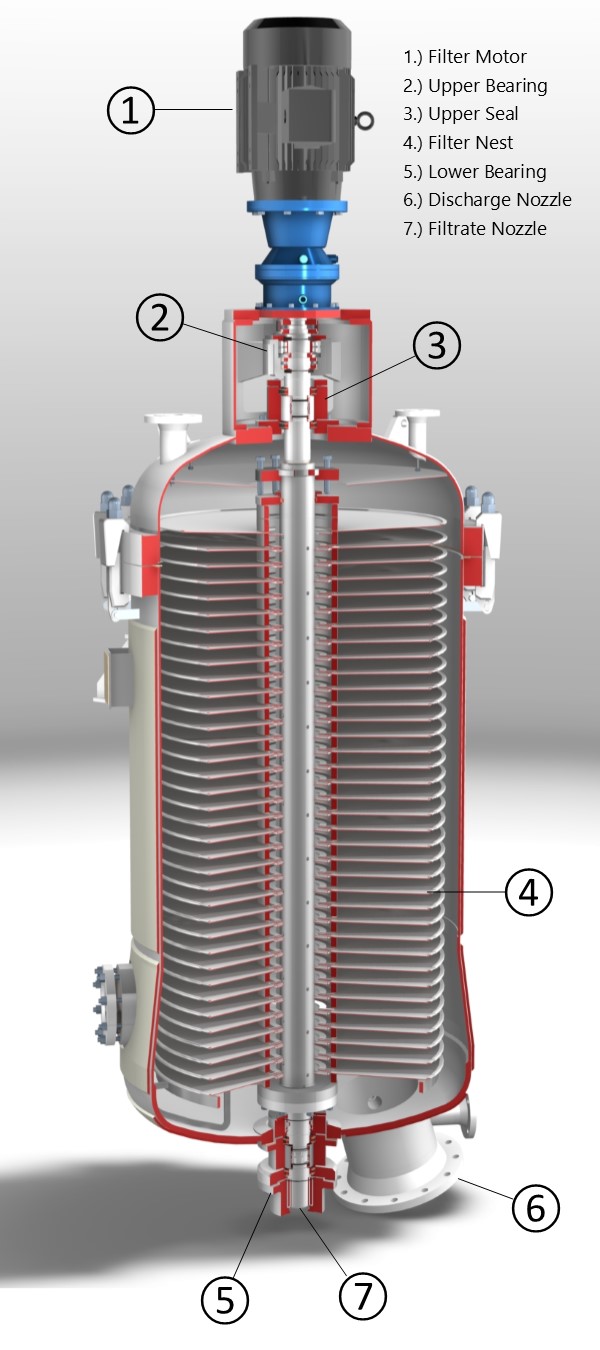

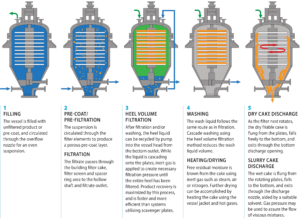

The vessel is filled with unfiltered product or pre-coat, and circulated through the overflow nozzle for an even suspension.

Pre-Coating

Pre-coating is the process where a suitable a material is deposited on the filter screens prior to filtration of the product. The suspension is circulated through the filter elements to produce a porous pre-coat layer.

Pre-Filtration

Pre-Filtration is generally recommended prior to the filtration operation. This step is identical to the filtration step except the product is circulated back to the feeding tank, ensuring a clear filtrate is being obtained.

Cake Filtration

The filtrate passes through the building filter cake, filter plate and spacer ring area to the hollow shaft and filtrate outlet. Once filtration is complete, the vessel is full of unfiltered liquid. This liquid can be also filtered by applying inert gas to the top of the filter vessel, thus forcing the liquid through the filter plates until all of the solids is deposited on the plates. Some liquid is left below the bottom most plate. This is the heel.

Heel Volume Filtration

After filtration and/or washing, the heel liquid can be recycled by pump into the vessel head from the bottom outlet. While the liquid is cascading onto the plates, inert gas is also applied to create the necessary filtration pressure until the entire heel has been filtered. Product recovery is maximized by this process, which is faster and more efficient than systems utilizing scavenger plates.

Cake Washing

The wash liquid follows the same route as in filtration. Cascade washing using the heel volume filtration method reduces the wash liquid volume.

Cake Drying

The cake can be heated and dried in the vessel using hot gases, such as steam, air or nitrogen. As a more efficient alternative to a steady flow of nitrogen in drying, the vessel can be repeatedly pressurized and quickly evacuated, dramatically reducing nitrogen usage.

Slurry Cake Discharge

The wet cake is flung from the rotating plates, falls to the bottom, and exits through the discharge nozzle, aided by a suitable solvent. Gas pressure may be used to assure the flow of viscous mixtures.

Dry Cake Discharge

As the filter nest rotates, the dry friable cake is flung from the plates, falls freely to the bottom, and exits through the bottom discharge opening.

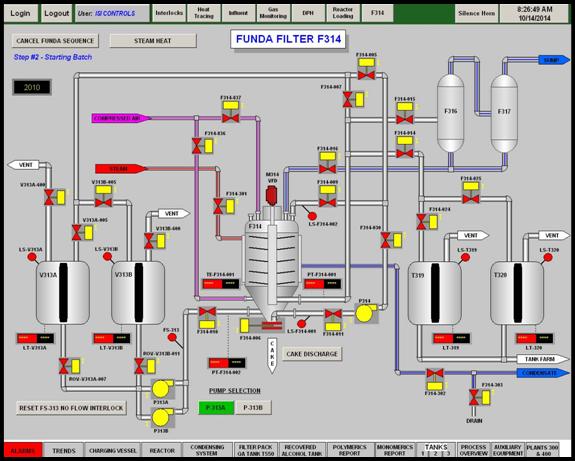

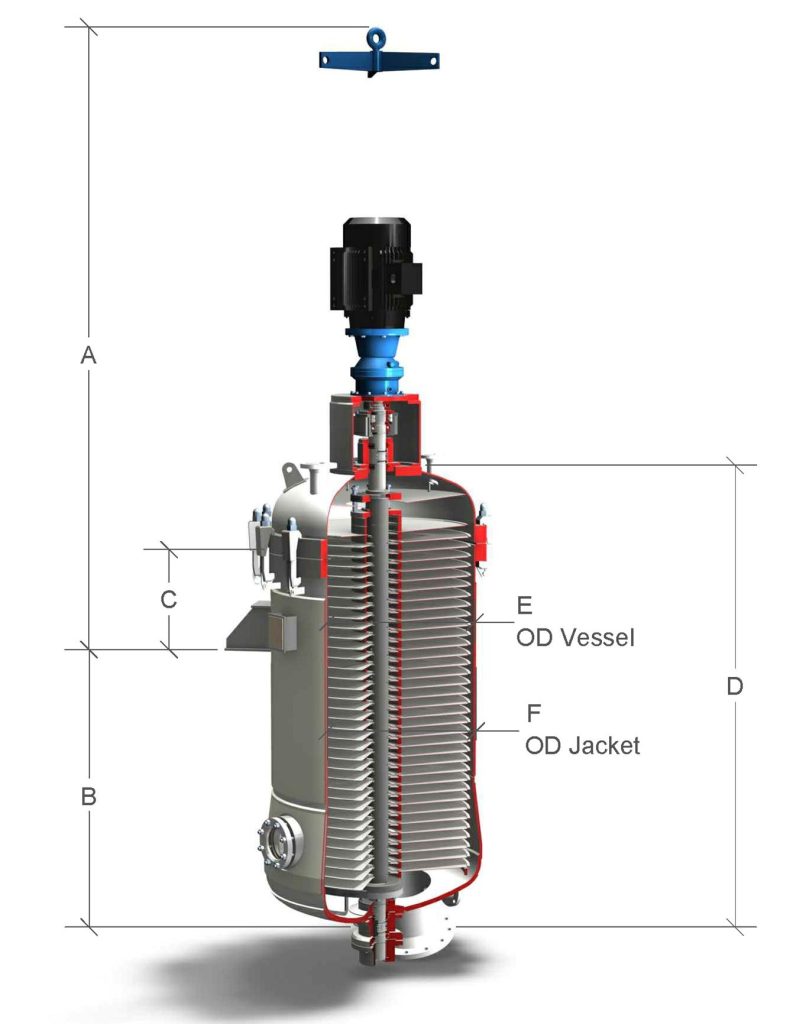

Completely Automated FUNDA Cake Filtration

Completely automatic filtration systems eliminate manual filter cleaning. FUNDA filtration provide completely automatic treatment in solid-liquid separation processes.

Horizontal filter discs ensure even cake build-up. The entire system can be automated and there is a unique device to filter the entire heel. The cake can be washed or extracted with solvent while still on the filter plates without disturbing the cake.

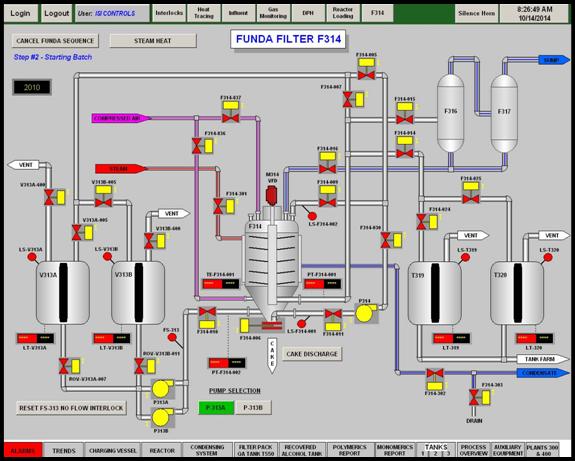

The key to producing a quality product using Steri Filters is process integration. Steri engineering works with you early-on to create a complete filtration process sequence. Part of the sequence development includes an evaluation of your overall system that results in recommended upgrades to your system. Giving you the best performance possible from your new Steri filter. The sequence, which is presented in HMI screenshots, includes all the steps required such as filling, pre-coat, filtration, washing, re-slurrying, drying, discharge and clean-in-place.

Filling

Filling